Y2 series motor rotor laminations suppliers

Y2 Series Motor Rotor Laminations Suppliers Overview The Y2 series motor is a widely used three-phase asynchronous motor known for its efficiency, reliability, and cost-effectiveness. A critical component of these motors is the rotor lamination stack, which plays a vital role in reducing energy losses, improving magnetic flux distribution, and ensuring smooth operation. Suppliers of Y2 series motor rotor laminations must adhere to strict material, design, and manufacturing standards to meet industry requirements. Material Selection High-quality rotor laminations for Y2 motors are typically made from silicon steel (electrical steel) due to its excellent magnetic properties and low core loss. The material grade, thickness (usually between 0.35mm and 0.5mm), and insulation coating (such as C5 or C6) are carefully selected to minimize eddy current losses and enhance motor efficiency. Suppliers must ensure consistent material quality to avoid performance variations. Precision Manufacturing Processes The production of rotor laminations involves precision stamping or laser cutting to achieve tight tolerances and smooth edges. Advanced tooling and die designs are essential to maintain dimensional accuracy, especially for the slots and keyways that accommodate rotor bars. Some suppliers also offer custom designs to meet specific motor performance criteria. Quality Control and Testing Reputable suppliers implement rigorous quality control measures, including dimensional inspections, material testing, and stacking factor verification. Eddy current testing and visual inspections ensure defect-free laminations. Proper stacking and alignment are crucial to prevent motor vibration and noise. Customization and Flexibility Suppliers often provide tailored solutions based on customer requirements, such as different slot configurations, stacking heights, or insulation treatments. Custom coatings or heat treatments may also be applied to enhance durability and performance. Global Supply Chain and Compliance Leading suppliers operate within a global supply chain, ensuring timely delivery and competitive pricing. Compliance with international standards (e.g., IEC, NEMA) is essential for manufacturers serving diverse markets. Conclusion Suppliers of Y2 series motor rotor laminations must combine advanced manufacturing techniques, strict quality control, and material expertise to deliver high-performance components. Their role is critical in ensuring the efficiency and longevity of Y2 motors across industrial, commercial, and automotive applications.

Products

Category:

-

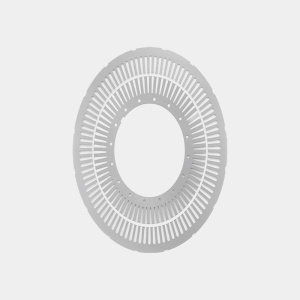

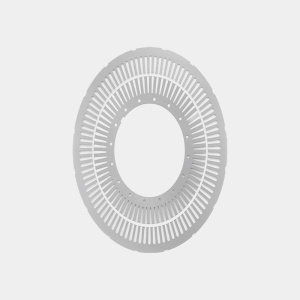

Y2 series motor rotor laminations

Category: Motor stator and rotor laminationsBrowse number: 144Number:Release time: 2025-09-30 15:12:27Y2 series motor rotor laminations are precision-engineered components designed to optimize the magnetic performance and efficiency of three-phase induction motors. Manufactured from high-quality silicon steel, these laminations minimize eddy current and hysteresis losses, enhancing motor efficiency and reducing heat generation. Their accurate dimensions, smooth edges, and uniform thickness ensure seamless assembly and mechanical stability under dynamic load. Suitable for industrial applications such as pumps, fans, compressors, and conveyors, Y2 series rotor laminations provide consistent torque, reliable performance, and extended motor lifespan. Trusted by motor manufacturers worldwide, these laminations play a critical role in achieving energy-efficient and durable motor operation.

News

Category:

No search results found!

Case

Category:

No search results found!

Video

Category:

No search results found!

Download

Category:

No search results found!

Job

Category:

No search results found!

Featured Products

No search results found!

Mobile: +86 13738592999

Mobile: +86 13738592999 Telephone: +86(576) 89307999

Telephone: +86(576) 89307999 E-mail: sales@zjxinzheng.com

E-mail: sales@zjxinzheng.com Address: Coastal Industrial City, Sanmen

Address: Coastal Industrial City, Sanmen

WhatsApp

WhatsApp Phone

Phone