Y2 series motor rotor laminations price

Pricing Analysis of Y2 Series Motor Rotor Laminations The pricing of Y2 series motor rotor laminations is influenced by multiple factors, including material costs, production processes, design specifications, and market demand. Below is a detailed breakdown of the key elements affecting their price: 1. Material Costs The primary material used for rotor laminations is electrical steel (silicon steel), which accounts for a significant portion of the total cost. The grade and thickness of the steel (typically 0.35mm to 0.5mm) impact performance and pricing. Higher-quality silicon steel with lower core loss properties commands a premium price. Additionally, fluctuations in global steel prices due to supply chain disruptions or trade policies can lead to cost variations. 2. Manufacturing Process Rotor laminations are produced through precision stamping or laser cutting, followed by stacking and insulation treatment. The complexity of the rotor design (e.g., number of slots, shape, and size) affects tooling and production costs. High-volume orders typically reduce per-unit costs due to economies of scale, while custom or low-volume batches may incur higher prices. 3. Design Specifications The Y2 series follows specific efficiency and performance standards, influencing lamination dimensions and tolerances. Tighter tolerances and advanced coatings (such as insulation varnish) to reduce eddy current losses may increase costs. Additionally, rotor lamination stacks must meet precise balancing requirements, adding to production expenses. 4. Market Demand & Competition Pricing is also shaped by market dynamics. Increased demand for energy-efficient motors can drive up costs, while competition among suppliers may lead to price reductions. Regional factors, such as labor costs and logistics, further influence final pricing. 5. Additional Cost Factors - Surface Treatment: Insulation coatings or heat-resistant treatments add to material expenses. - Quality Control: Strict testing for dimensional accuracy and magnetic properties increases production costs. - Packaging & Logistics: Bulk shipping or specialized packaging for corrosion protection affects pricing. Conclusion The price of Y2 series rotor laminations varies based on material selection, production efficiency, design complexity, and market conditions. Buyers should evaluate suppliers based on quality, lead times, and cost-effectiveness to ensure optimal value. For precise pricing, manufacturers typically provide quotations after reviewing technical specifications and order volumes.

Products

Category:

-

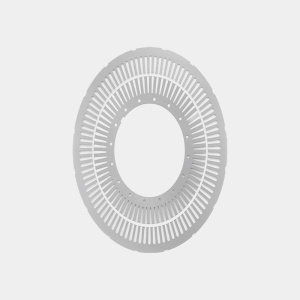

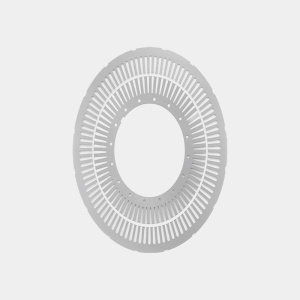

Y2 series motor rotor laminations

Category: Motor stator and rotor laminationsBrowse number: 144Number:Release time: 2025-09-30 15:12:27Y2 series motor rotor laminations are precision-engineered components designed to optimize the magnetic performance and efficiency of three-phase induction motors. Manufactured from high-quality silicon steel, these laminations minimize eddy current and hysteresis losses, enhancing motor efficiency and reducing heat generation. Their accurate dimensions, smooth edges, and uniform thickness ensure seamless assembly and mechanical stability under dynamic load. Suitable for industrial applications such as pumps, fans, compressors, and conveyors, Y2 series rotor laminations provide consistent torque, reliable performance, and extended motor lifespan. Trusted by motor manufacturers worldwide, these laminations play a critical role in achieving energy-efficient and durable motor operation.

News

Category:

No search results found!

Case

Category:

No search results found!

Video

Category:

No search results found!

Download

Category:

No search results found!

Job

Category:

No search results found!

Featured Products

No search results found!

Mobile: +86 13738592999

Mobile: +86 13738592999 Telephone: +86(576) 89307999

Telephone: +86(576) 89307999 E-mail: sales@zjxinzheng.com

E-mail: sales@zjxinzheng.com Address: Coastal Industrial City, Sanmen

Address: Coastal Industrial City, Sanmen

WhatsApp

WhatsApp Phone

Phone