Selecting the right motor stator is a critical step in ensuring the efficiency, reliability, and longevity of HVAC (Heating, Ventilation, and Air Conditioning) systems. The stator, as the stationary part of an electric motor, plays a vital role in converting electrical energy into mechanical motion. Given the diverse operating conditions and performance requirements of HVAC systems, choosing the appropriate stator involves careful consideration of several factors. Below are key tips to guide you through the selection process.

1. Understand the Basics of Motor Stators

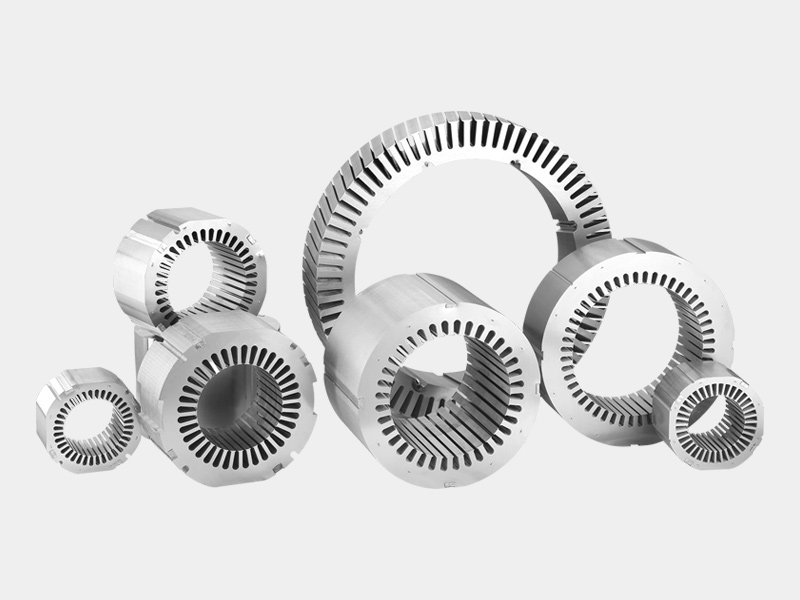

Before diving into selection criteria, it’s essential to grasp the fundamentals of motor stators. The stator consists of a laminated core with windings that generate a rotating magnetic field when energized. This field interacts with the rotor to produce torque. In HVAC applications, stators are commonly found in motors driving fans, compressors, and pumps.

Key components of a stator include:

- Laminated Core: Reduces eddy current losses and improves efficiency.

- Windings: Copper or aluminum coils that carry current.

- Insulation Materials: Protect windings from heat and electrical faults.

2. Match Stator Specifications to HVAC Requirements

HVAC systems operate under varying loads and environmental conditions. To select the right stator, align its specifications with the system’s demands:

- Power Rating: Ensure the stator can handle the motor’s power requirements without overheating.

- Voltage and Frequency: Match the stator to the power supply (e.g., 120V/60Hz or 230V/50Hz).

- Efficiency Class: Opt for stators that meet or exceed industry standards (e.g., IE3 or IE4 for energy efficiency).

3. Consider the Operating Environment

HVAC motors often face harsh conditions, such as high temperatures, humidity, or dust. The stator must withstand these challenges:

- Temperature Resistance: Choose stators with high-temperature insulation (e.g., Class F or H) for prolonged operation in hot environments.

- Moisture and Corrosion Protection: In humid or coastal areas, stators with moisture-resistant coatings or sealed designs are preferable.

- Dust and Debris: For dusty environments, stators with protective enclosures (e.g., IP54 or higher) are ideal.

4. Prioritize Energy Efficiency

Energy efficiency is a top priority in modern HVAC systems. A well-designed stator can significantly reduce power consumption:

- High-Quality Materials: Copper windings offer lower resistance and better efficiency than aluminum.

- Optimized Core Design: Thin, high-grade laminations minimize energy losses.

- Advanced Winding Techniques: Precision winding reduces gaps and improves magnetic flux.

5. Evaluate Thermal Management Capabilities

Overheating is a common cause of motor failure. The stator’s thermal performance is crucial:

- Cooling Methods: Stators in HVAC motors often rely on air or liquid cooling. Ensure adequate ventilation or cooling mechanisms.

- Thermal Class: Select stators rated for the expected operating temperature range (e.g., Class B for 130°C, Class F for 155°C).

6. Assess Mechanical Durability

Vibration and mechanical stress can degrade stator performance over time:

- Robust Construction: Look for stators with reinforced cores and windings to withstand vibration.

- Balanced Design: Improperly balanced stators can lead to noise and premature wear.

7. Compatibility with Motor Type

HVAC systems use various motor types, such as induction, permanent magnet, or ECM (Electronically Commutated Motors). Ensure the stator is compatible with the motor’s design:

- Induction Motors: Stators must produce a strong rotating magnetic field for reliable startup and operation.

- Permanent Magnet Motors: Stators should work seamlessly with the rotor’s magnetic field for high efficiency.

8. Noise and Vibration Considerations

Excessive noise can be a concern in residential or commercial HVAC applications:

- Low-Noise Stators: Precision manufacturing and balanced windings reduce electromagnetic noise.

- Vibration Damping: Stators with anti-vibration features enhance system quietness.

9. Longevity and Maintenance Requirements

A durable stator reduces downtime and maintenance costs:

- High-Quality Insulation: Prevents short circuits and extends lifespan.

- Easy Maintenance: Stators with accessible windings simplify inspections and repairs.

10. Compliance with Industry Standards

Ensure the stator meets relevant standards for safety and performance:

- International Standards: Look for certifications like IEC, NEMA, or UL.

- Local Regulations: Compliance with regional energy efficiency and safety codes is essential.

Conclusion

Selecting the right motor stator for HVAC systems requires a thorough understanding of technical specifications, environmental conditions, and performance goals. By focusing on efficiency, durability, and compatibility, you can optimize your HVAC system’s reliability and energy savings. Always consult technical datasheets and, if necessary, seek expert advice to make an informed decision.

By following these tips, you can ensure that the motor stator you choose will deliver optimal performance, reduce operational costs, and extend the lifespan of your HVAC system.

Copyright © Zhejiang Xinzheng Electromechanical Technology Co., Ltd. All Rights Reserved.

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)